Simple-Aligner – Automatic component measurement for Autodesk Inventor

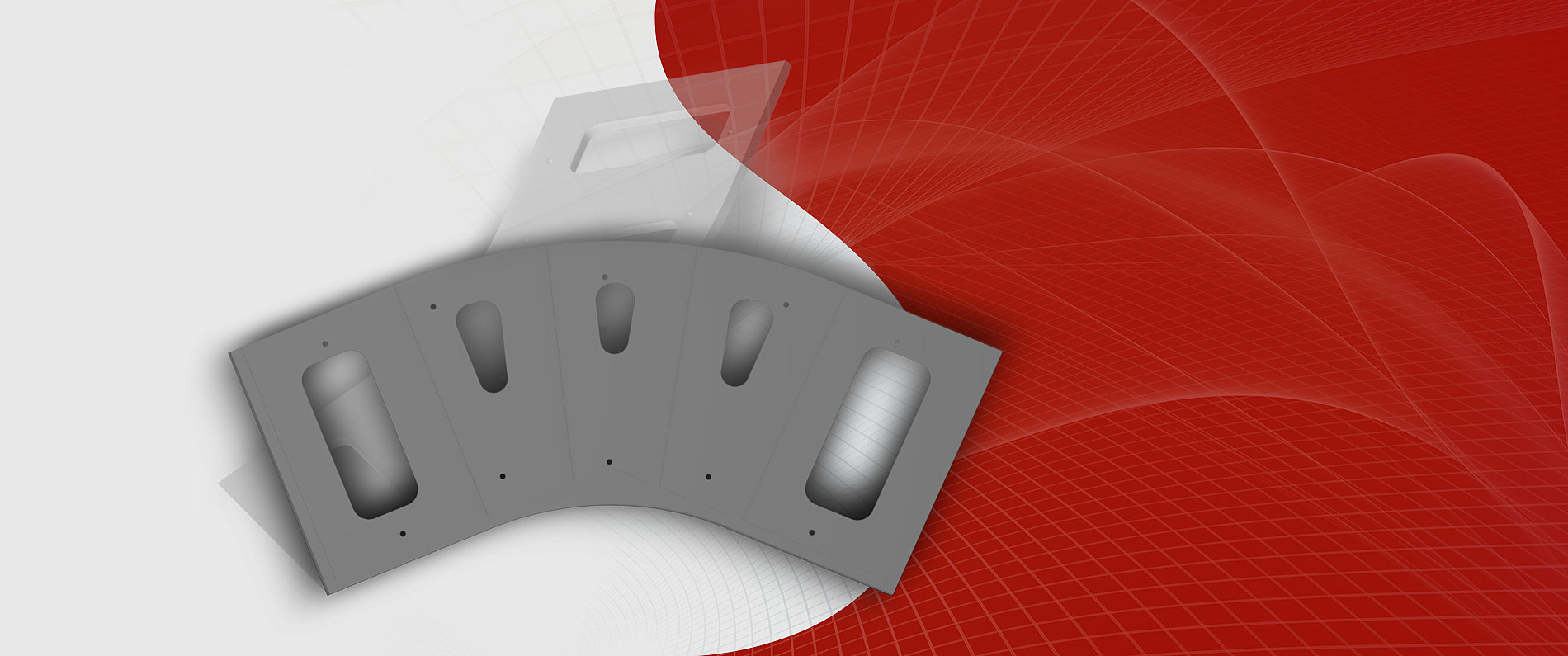

The high-performance extension tool Simple-Aligner allows you to automatically create measurements of individual components or all components in an entire assembly.

At any time during the design phase you can check if the parts are fit for manufacturing. As a next step, the dimensions that have been created automatically will be used to determine the raw materials needed.

When determining the dimensions during pre-production Simple-Aligner allows you to simultaneously align all parts with the baseline without damaging existing assemblies. Parts are aligned according with the zero point of the production machines used. Simple Aligner will determine the lowest possible raw material consumption when building individual parts. The design method used is of no importance here.

Any part with a solid model can be aligned with the baseline.

Simple-Aligner includes the following functions:

- Automated creation of dimensions for individual parts and complete assemblies, regardless of where the part is situated in the coordinate system

- Required raw materials are determined automatically

- Preparation for subsequent export to *.xls or *.csv file formats or to an ERP system.

- Alignment of parts with zero point of production machines

- Arrangement of parts according to lowest possible volume

- Dimensions of beams, pipes and sections are determined as well

- For easy CAM detection miter joints are colored in automatically

Your benefits of working with Simple-Aligner:

- Save time through automation of routine tasks

- Cut costs through optimal positioning of parts

- Minimize errors through generated operating processes

- Improve quality management through better monitoring options

- Optimize design and manufacturing processes

- Create production assemblies

Other Simplifiers Products:

Using the innovative export interface Simple-Export data can be exported from Autodesk Inventor to excel format or CSV file format. What's more, it is possible to transfer the data to an ERP system.

(0 36 95) 85 83 966